Description

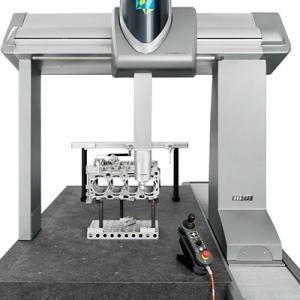

Leitz PMM-F

Leitz PMM-F 30.20.10/16 – High performance CMM & gear inspection centre

Leitz PMM-F 30.20.10 and 30.20.16 measuring machines – where accuracy meets throughput. The PMM-F is designed to inspect medium sized components and gears not only with maximum accuracy, but with a high throughput as well. The spindle drive design combined with an overhead structure with minimized mass allows measuring velocities previously unthinkable for measuring machines of this size.

The Leitz PMM-F is a high-accuracy monolithic gantry measuring machine for medium sized workpieces. It achieves high throughput with highest possible accuracy on the shop floor or in the measuring room. The PMM-F is also available with a large measuring volume of up to 9.6 m3. It does not require costly foundations and can therefore be easily moved. Every Leitz PMM-F measuring machine is equipped with an integrated active vibration damping system.

The Leitz LSP-S2 high performance probe head allows High-Speed-Scanning and can handle stylus length of up to 800 mm.

The Leitz PMM-F gear inspection center provides several advantages compared to a conventional single purpose gear testers:

- They are much more flexible, as not only gears but any component can be measured.

- Leitz gear inspection systems work without a rotary table, i.e. alignment or centering of the gear is not required.

- Unrivalled throughput by automatically measuring a large number of gears on one pallet

- Complete inspection of gears mounted on long shafts of up to 3000 mm

- All datums are measured as specified in the drawing, even in large internal gears.

Features

- Moving gantry in Overhead Design with minimized moving mass

- Massive U-frame, completely made of granite

- Ceramic Z-ram

- Dual ball spindle drives and dual scales in X

- Leitz LSP-S2 probe system, suitable for stylus extensions up to 800 mm

- Integrated active pneumatic damping system, no foundation required

Reviews

There are no reviews yet.