Description

MAXIMUM PERFORMANCE VERTICAL TURNING CENTERS

Packed with industry leading technology and top quality components, the Goodway GV-1 series vertical turning centers combine incredible power, strong constructions, and heavy duty cutting capabilities to bring you The Ultimate Machining Power®. These maximum performance machines will easily accomplish the demanding turning applications of today and tomorrow. With maximum turning diameter up to 70.9″, maximum weight load up to 17,600 lb, and available live tooling spindle & Cf-axis capabilities, turning, milling, contour milling and drilling applications may be completed in one single machine.

- The high-rigidity vertical turning center construction, can easily overcome horizontal turning centers’ problems when machining large-diameter, heavy-weight and non-symmetrical work pieces.

- Fully enclosed splashguards keep chips and coolant contained for a safe clean working environment.

- Extra wide door width up to 82.7″ ( GV-1200 : 70.9″ ) enables large size work pieces to be loaded onto the work table with a crown block providing easy loading and unloading operations.

| Models | GV-1200 | GV-1600 |

|---|---|---|

| Max. swing diameter | Ø 63.0″ ( 1,600 mm ) | Ø 78.7″ ( 2,000 mm ) |

| Max. turning diameter | Ø 53.1″ ( 1,350 mm ) | Ø 70.9″ ( 1,800 mm ) |

| Max. turning length | 51.2″ ( 1,300 mm ) | 51.2″ ( 1,300 mm ) |

| Max. weight load | 11,000 lb ( 5,000 kg ) | 17,600 lb ( 8,000 kg ) |

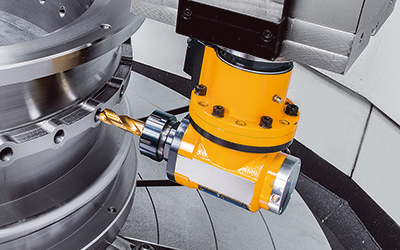

| Live tooling spindle | Optional | Optional |

Specifications are subject to change without notice.

- High rigidity work table with a standard 4-jaws individual manual chuck provides easy operation and outstanding heavy-duty cutting capability.

- With the outstanding chip disposal design, chips can be easily brought out through the coolant tank and chip conveyor to the chip cart.

- Super large 900L coolant tank capacity allows smooth coolant circulation which tremendously improves the machine’s overall accuracy by lowering thermal expansion effects to a minimum.

- The coolant system features a roll-out coolant tank for easy maintenance.

- Right discharge chip conveyor can be equipped with a programmable controller to minimize coolant loss and increase chip disposal efficiency.

- Standard BT-50 16-tool umbrella type ATC with fully enclosed guarding can be equipped with various turning, milling, and drilling tools based on different turning applications.

- The auto lubrication system delivers metered amounts of lubrication to the slide ways, ball screws, and vital components. Distribution is automatically shut off during idling to prevent waste.

Reviews

There are no reviews yet.