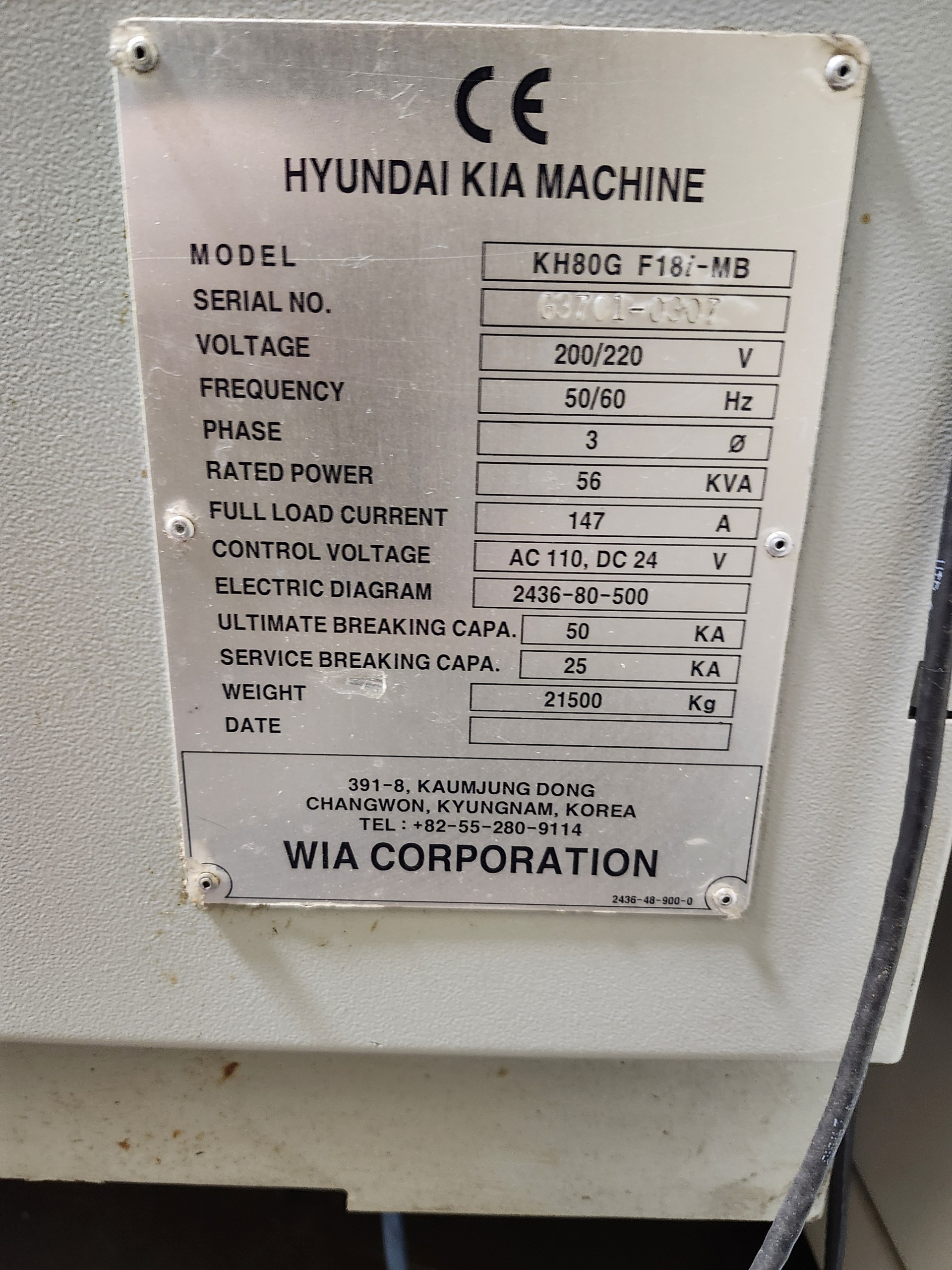

2011 Hyundai KH80G Horizontal Machining Center

Lamarche Machinery Inc., 8821, 60 Avenue NW, Davies Industrial West, South Industrial District, Edmonton, Alberta, T6E 6L9, Canada👁 372

Address

Open on Google Maps- Address Lamarche Machinery Inc., 8821, 60 Avenue NW, Davies Industrial West, South Industrial District, Edmonton, Alberta, T6E 6L9, Canada

- City Edmonton

- State/county AB Canada

- Zip/Postal Code T6E 6L9

- Country Canada

Details

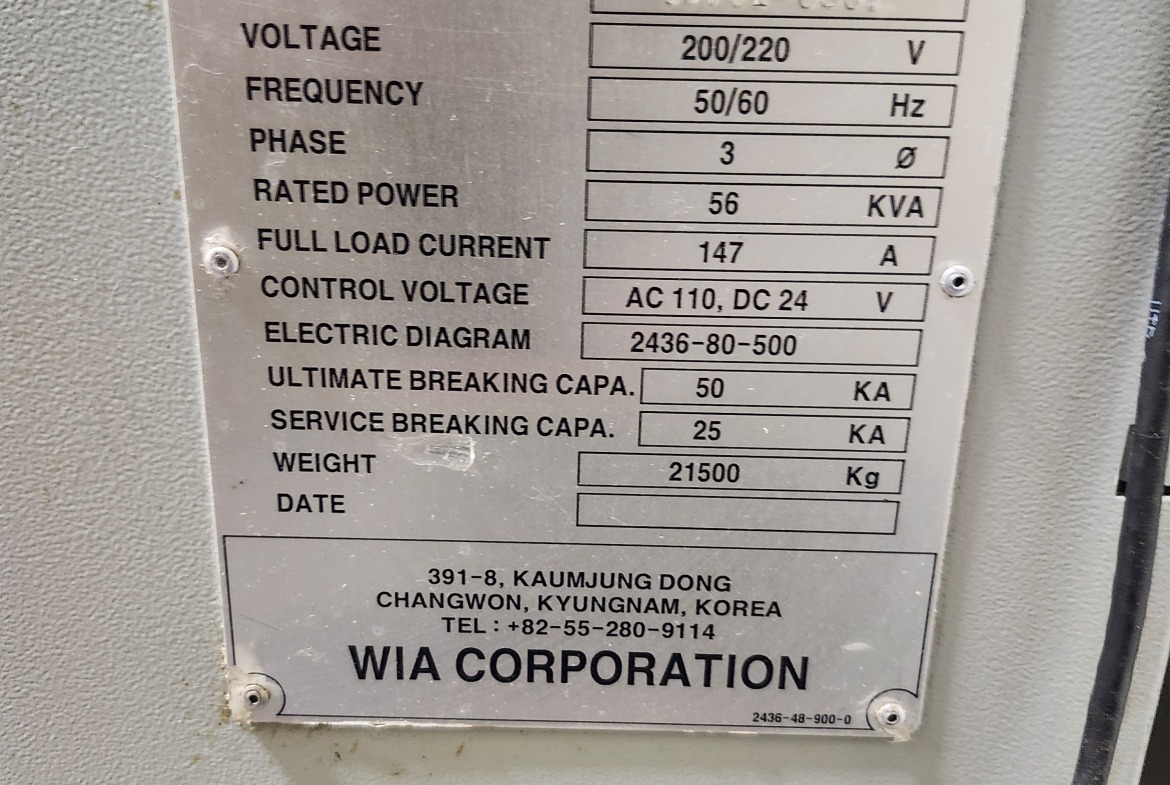

Updated on October 3, 2025 at 5:21 pm- Listing ID: KH80G

- Year Built: 2011

Description

| 2011 USED KH80G Horizontal Machining Center | |

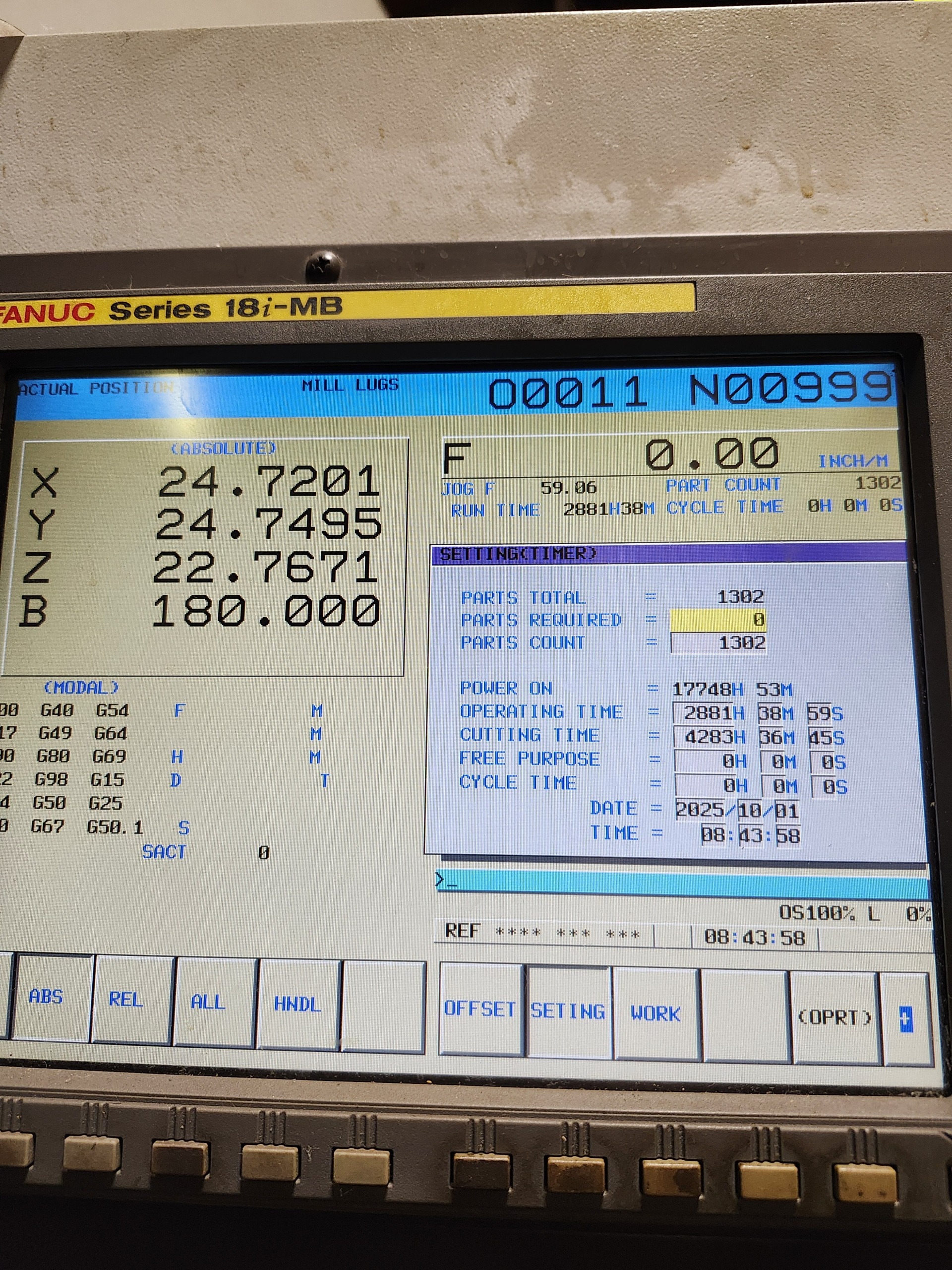

| Controller with 10.4″ Color LCD | Fanuc 31i-B 10.4″ |

| Travel X,Y,Z | 49.2″ x 39.4″ x 33.5″ |

| Table (2) | 31.5″x31.5″ |

| Max Table Weight Per Table (2) | 4,850 lbs |

| Work Piece ( Dia X Height ) | 45.3″ X 45.3″ |

| Indexing | 0.001 degree |

| Pallet Changing Method | Shuttle Type |

| Pallet Change time | 28 seconds |

| Spindle Center to Table Surface Distance | 1.97″ ~ 41.3″ |

| Spindle Nose to Table Centre Distance | 9.8″ ~ 43.3″ |

| Spindle Taper | CAT 50 |

| Spindle Speed | 4,500 rpm |

| Horsepower | 35 HP (26KW) |

| Number of Gear Ranges | 3 Speed Geared Head |

| Spindle Torque | 1,110 Ft-lbs |

| Tool Magazine – Twin Arm | 80 Tool |

| Tool Change Time | 3.5 Sec |

| X,Y, and Z axis rapid travers rate | 709 ipm |

| Cutting Feed | .04-315 ipm |

| Weight | 47,399 lbs |

| Floor Space (L) w/ Chip conveyor & Tank | 159.4″ |

| Floor space (W) | 263.7 |

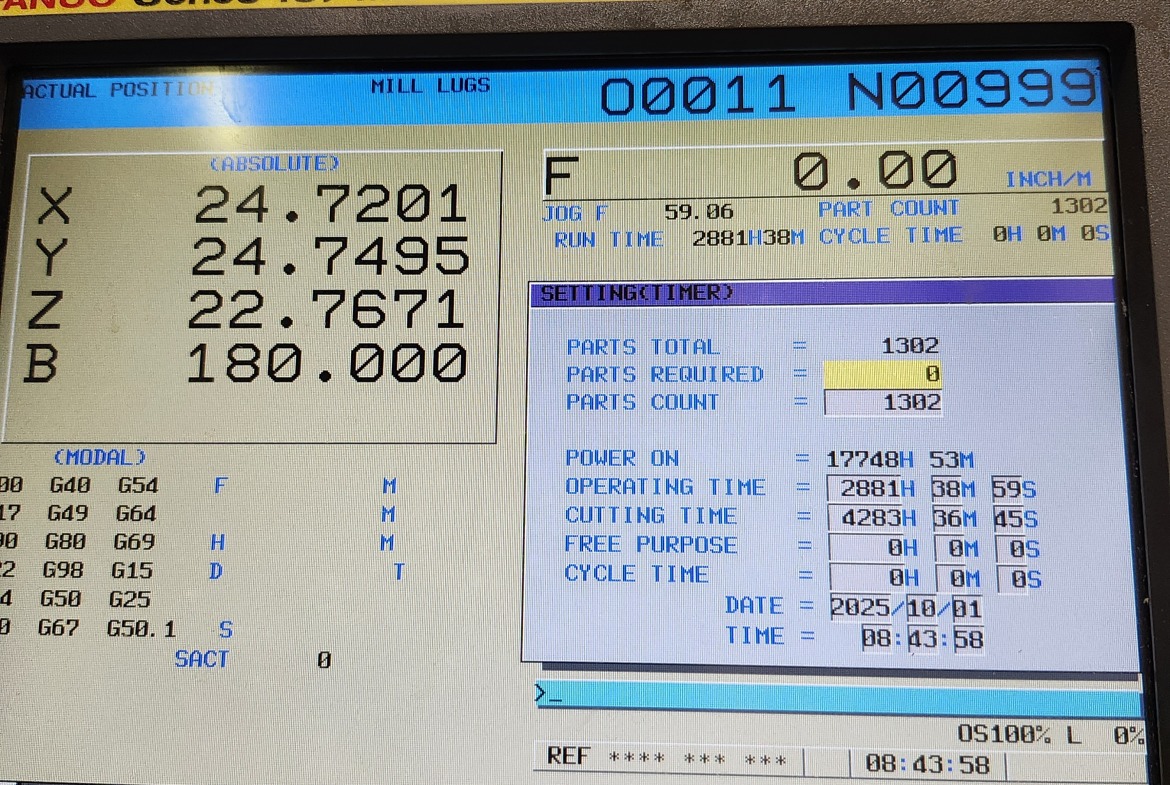

| Power required | 56kva/147 amp @ 220v |

| Voltage | 205-235 volts / 3 phase |

| Coolant Thru Spindle | 6bar (87 psi) |

| Optional Equipment Included | |

| Chip Conveyor Rear | |

| Remote MPG | Pulse Generator |

| A02B-0284-J919 Additional Work Coordinate System(300 Pairs) | |

| Additional work coordinate 48 pair | |

| Spiral / conical Interpolation | |

| Coordinate System Rotation | |

| Part program storage | |

| MODULE, (FROM 32MB, SRAM 3MB) | |

| UPGRADE PART PROG STORAGE 2560 M | |