Description

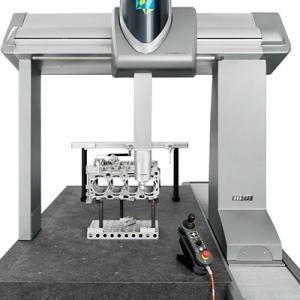

DEA ALPHA 2.0

Flexible Gantry Coordinate Measuring Machine for Large Workpieces

DEA ALPHA 2.0 is an all-purpose gantry coordinate measuring machine (CMM) suited to the dimensional inspection of large workpieces such as castings and machined parts. Equipped with both tactile probes and a 3D laser scanning head, it can rapidly acquire millions of data points from complex contoured shapes and is the ideal system for measuring large-volume components as well as 3D surfaces.

For over 40 years, Hexagon Manufacturing Intelligence has been the unrivalled market leader in gantry CMMs. Superior technology, innovative solutions and constant development in collaboration with customers has led to hundreds of installations worldwide. The gantry architecture is the ideal solution for all measurement applications on large-sized automotive and aerospace components, as well as heavy transportation, communication and satellite equipment. Designed without central pillars, the CMM offers easy access to the measurement volume and easy loading and integration with part transportation systems, alongside world-class dynamics and accuracy performance.

DEA ALPHA 2.0 is available in two versions: DEA ALPHA 2.0 Classic and DEA ALPHA 2.0 Performance. All DEA ALPHA 2.0 versions can be supplied with optional bellows and covers which offer the CMM protection from airborne shop contaminants.

The DEA ALPHA 2.0 Classic is a multi-purpose flexible CMM for the dimensional inspection of large castings and machined parts. When equipped with optical scanning sensors, the system can rapidly digitise millions of data points on freeform components. It is therefore an ideal reverse engineering and inspection system for the die and mould manufacturing process.

DEA ALPHA 2.0 Performance is a high-performance gantry CMM that, thanks to its high-rigidity silicon carbide ram and sophisticated multisensor temperature compensation, guarantees high accuracy and ease of use under all operating conditions.

Features

- Slant Bridge technology on the X axis

- Reinforced right shoulder

- High-rigidity mechanical structure with no need for central pillars

- Low-mass aluminium alloy on main carriage (X and Z axes)

- Z-ram made in aluminium alloy or sintered silicon carbide

- Continuous axes motion interpolation

- High-throughput non-contact sensor options

- HH-ACW-43MW continuous wrist available as option

- Bellows kit available as option

- Multisensor temperature compensation

Reviews

There are no reviews yet.