Description

HIGH SPEED CNC TURNING CENTERS

With the latest machine tools technology and precision turning performance, GOODWAY brings you the new GLS-1500 series high speed CNC turning center. Using 2 types of bed combined with super rigidity, high speed turning capability and compact size provides you with super efficiency cutting power. The GLS-1500 series equipped with an optional live tooling turret, Y-axis and sub-spindle can work on turning, milling, drilling tasks at the same time to increase the output capacity with high end value to meet your needs of today and tomorrow.

- 30˚ slant-bed design provides smooth chip disposal and easier operator access.

- Steel way covers and special steel wipers molded with industrial strength rubber are used for durability.

- Fully enclosed splashguards keep chips and coolant contained for a safe clean working environment.

- The auto lubrication system delivers metered amounts of lubrication to the slide ways, ball screws, and vital components. Distribution is automatically shut off during idling to prevent waste.

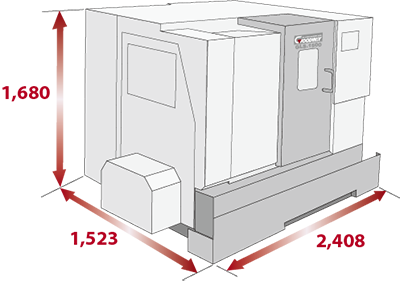

- Z-axis carriage manual locks onto the tailstock base and moves it to the desired position with precision accuracy.

- The extension of the shaft can be controlled by program, which makes it easier to insert the center into the center hole.

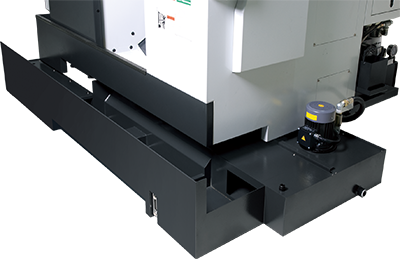

- Large 100L separate type coolant tank provides optimal heat dispersion and lower coolant temperature, which will help extend coolant life.

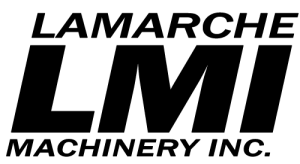

- Compact structure and cover design minimizes factory space usage which increases efficiency.

Reviews

There are no reviews yet.